By:Abhishek Shah

The supply chain is crucial in today’s dynamic world of mobility and smartphones. Automation has become vital in managing supply chain operations, allowing companies to enhance efficiency, cut costs, and boost customer satisfaction. However, the successful implementation of automation hinges on selecting the right technology partner.

This article digs into crucial considerations and challenges when choosing a technology partner for automation in the mobility and smartphone reverse logistics supply chain.

Key Factors to Consider When Choosing a Technology Partner

Selecting the perfect technology partner can make all the difference in a successful automation project. Here are some factors to ponder:

Expertise and Experience:

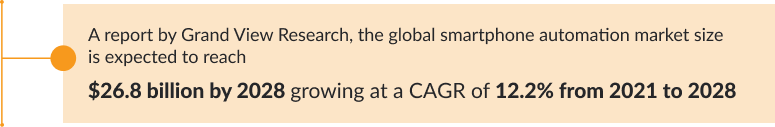

A technology partner’s knowledge and experience in implementing automation solutions within the mobility and smartphone supply chain are paramount. You need a partner with a proven track record of successful implementations. This minimizes risks and ensures a smooth and efficient rollout. A partner with specific experience in your industry can bring invaluable insights to the table. According to a report by Grand View Research, the global smartphone automation market size is expected to reach $26.8 billion by 2028, growing at a CAGR of 12.2% from 2021 to 2028. This growth is driven by the increasing demand for smartphones, the growing complexity of the smartphone supply chain, and the need to improve efficiency and productivity. Phoenix Innovations is well-positioned to capitalize on this growth. We are a leading provider of automation solutions for the mobility and smartphone supply chain. The company has a proven track record of success, having implemented automation solutions for some of the world’s leading smartphone manufacturers.

Industry Knowledge:

Your technology partner should understand the unique challenges and intricacies of the mobility and smartphone supply chain, especially in reverse logistics for returns processing. Familiarity with the nuances of this sector is crucial for tailoring automation solutions to your specific needs. According to Gartner, the average cost of returns for smartphones is $100 per device. This is a significant cost that can be reduced through automation.

Scalability and Flexibility:

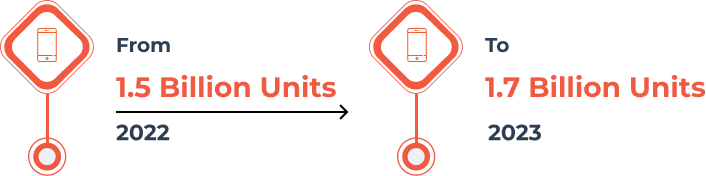

In a rapidly evolving mobility industry, your technology partner must support scalability and adapt to the changing operational requirements, especially in returns processing. They should offer flexibility to accommodate varying data volumes and operational demands, particularly during peak returns seasons. The global smartphone market is expected to reach 1.7 billion units in 2023, up from 1.5 billion in 2022. This growth will strain the supply chain, and companies must find ways to automate their operations to keep up.

Expected Global Smartphone Market To Reach

Integration Capabilities:

Seamless integration with existing systems and processes is non-negotiable, particularly when handling returns efficiently. Your chosen partner should have a track record of successfully integrating their solutions with systems like yours. A study by Aberdeen Research found that companies that have successfully implemented automation solutions have seen a 30% reduction in the time it takes to process returns.

Support and Maintenance:

Ongoing support and maintenance services are invaluable in reverse logistics, especially for device returns processing. A proactive partner who can anticipate and resolve issues ensures the uninterrupted flow of operations, particularly during high-volume returns periods.

Challenges in Choosing the Right Technology Partner for Reverse Logistics While the benefits of a technology partnership are evident in reverse logistics for device returns processing, unique challenges persist:

Handling Returns Efficiently:

In the mobility and smartphone supply chain, efficiently processing returns is a significant challenge. Returned devices must be swiftly assessed, refurbished, or recycled to minimize losses and meet customer expectations. The average return rate for smartphones is 15%, which means that for every 100 smartphones sold, 15 will be returned. This can significantly strain the supply chain, as returned devices need to be processed quickly and efficiently. According to a study by the Aberdeen Group, companies implementing automation solutions for reverse logistics have seen a 20% reduction in the time it takes to process returns.

The average return rate for smartphones, which means that for every 100 smartphones sold, 15 will be returned.

Device Erasure and Data Security:

Efficiently erasing sensitive customer data from returned devices while maintaining data security is a significant challenge. A partner must ensure that erasure processes meet the compliance standards. A study by IBM found that 60% of companies that have experienced a data breach did not have a formal data erasure process.

Cosmetic Grading and Quality Control:

Consistently and accurately grading the cosmetic condition of returned devices is essential for resale. Automation can ensure uniform grading and quality control, reducing subjectivity and increasing the process’s accuracy. A study by the National Retail Federation found that the average cost of repairing a smartphone is $125.

Functional Testing and Refurbishment:

Efficiently testing and refurbishing returned devices are critical to maximizing their value. Automation today can streamline these processes, reducing the risk of incorrect testing and refurbishment due to operator exhaustion that can arise while testing and refurbishing large volumes of devices daily. A study by IDC (International Data Corporation) found that the average cost of refurbishing a smartphone is $75.

Device Storage and Retrieval:

Efficiently storing and retrieving returned devices within a warehouse is crucial. Automation can help perfect the storage and retrieval operations and reduce the risk of misplaced or lost devices. Most companies today face challenges in efficiently managing large volumes of processed devices and frequent reconciliation to keep the inventory updated. Automation can automate inventory management and asset storage, tracking, and retrieval. An Association for Supply Chain Management study found that the average cost of lost or damaged inventory is $100 per item.

Managing Returns During Seasonal Peaks:

Managing returns during seasonal peaks, such as after-holiday sales, can be overwhelming. Scalable solutions are essential to handle the sudden influx of returned devices. A study by the National Retail Federation found that the average return rate during the holiday season is 25%.

How can you elevate your Supply Chain needs with Phoenix Innovations?

In this dynamic landscape of mobility and smartphone supply chains, we’ve seen first-hand how technology can be a game-changer, particularly in reverse logistics of smartphones. Partnering with Phoenix Innovations provides a competitive edge for companies aiming to elevate their automation capabilities and streamline supply chain operations. We offer an all-encompassing suite of solutions that efficiently cover every aspect of returns processing. From receiving returned devices using Midas to automated erasure using TruWipe, automated cosmetic grading with Deepsight and Deepclean, and automated functional testing via Impersonator and TruChk, we have it all under one roof. Our expertise extends to providing packaging solutions through MsoftPack, and we excel in automated storage and retrieval, as well as bulk packaging and gift packaging solutions. As you explore the offerings on the Phoenix Innovations website, you’ll discover our capabilities and resources for enhancing mobile and smartphone supply chain processes, particularly in device returns management. If you’re interested in optimizing your operations and delivering a smoother, more satisfying experience to your customers, consider Phoenix Innovations as your technology partner. Your customers will appreciate the streamlined and effective returns management, and your business’s financial performance will reflect these improvements.

The Phoenix Group™ Companies

The Phoenix Group™ Companies